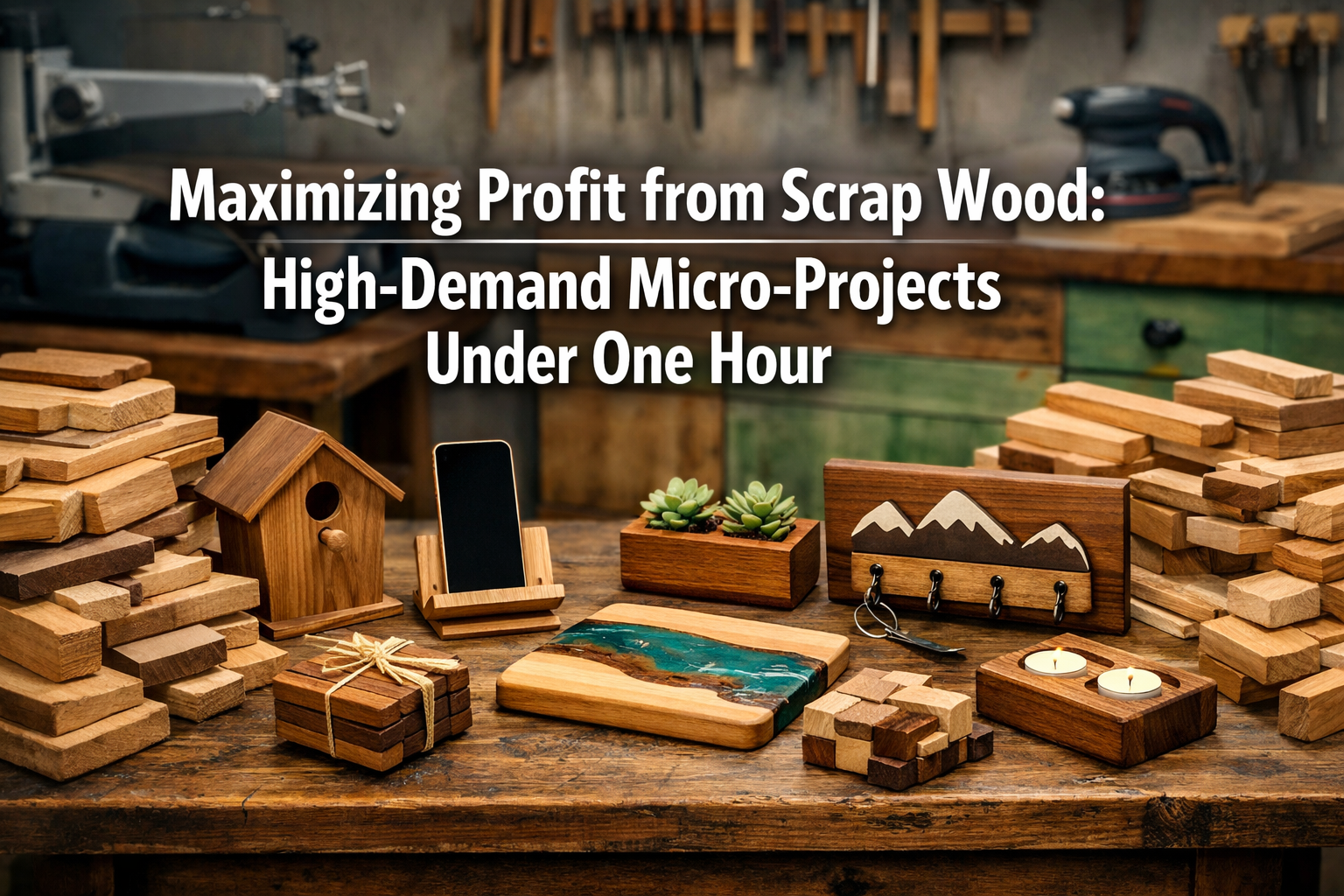

The hum of a table saw, the rich scent of sawdust, and the satisfaction of a perfectly cut joint are joys familiar to any woodworker. Yet, a common challenge often arises from these endeavors: the accumulation of scrap wood. Far from being mere waste, these offcuts and smaller pieces hold immense potential for profit if approached strategically. This article is a comprehensive guide to identifying which scrap wood projects have the highest market demand and profit margins, specifically focusing on micro-projects that can be completed in under one hour. By leveraging efficient production timelines and smart selling strategies, woodworkers can master the art of Maximizing Profit from Scrap Wood: High-Demand Micro-Projects Under One Hour.

In 2026, the demand for unique, handmade, and sustainable products continues to surge, creating a golden opportunity for artisans. Instead of discarding valuable wood remnants, transforming them into sought-after items can significantly boost income and reduce waste. This guide will delve into market analysis, project selection, rapid production techniques, and effective sales channels to help turn your workshop’s leftovers into a lucrative venture.

Key Takeaways

- Market Analysis is Crucial: Understand current trends and consumer preferences for small, handmade wooden items before committing to projects. Websites like Etsy, local craft fairs, and social media offer excellent insights.

- Focus on Micro-Projects: Prioritize items that can be completed, from cut to finish, in under one hour. This maximizes hourly output and profit potential.

- Efficiency is King: Streamline your workflow using jigs, templates, and batch processing to reduce production time for each item.

- Effective Finishing Matters: Simple, attractive finishes like food-safe oil, wax, or a clear coat can significantly enhance a project’s perceived value without adding much time. For specific techniques, consider exploring rustic wood finishing techniques or maple wood finishing techniques if working with maple.

- Strategic Selling: Utilize multiple sales channels, including online marketplaces, local craft shows, and direct-to-consumer options, to reach a broader audience and maximize sales.

Identifying High-Demand Micro-Projects for Maximizing Profit from Scrap Wood

Understanding consumer trends is the bedrock of successful product development. In 2026, buyers are increasingly seeking unique, artisanal goods that are both practical and aesthetically pleasing. For Maximizing Profit from Scrap Wood: High-Demand Micro-Projects Under One Hour, this translates into small, well-crafted items that offer utility, charm, or a touch of personalization.

Market Research: What’s Hot in 2026? 🔥

Before you even pick up a saw, dedicate time to market research. This isn’t just about guessing; it’s about observing and analyzing.

Online Marketplaces:

- Etsy: Browse the “Handmade” or “Woodworking” categories. Filter by “best sellers” or “trending” to see what customers are buying. Pay attention to pricing, popular finishes, and unique designs.

- Pinterest & Instagram: These platforms are visual treasure troves. Search for hashtags like #handmade #woodcrafts #scrapwoodprojects #smallbusiness and observe what kind of small wooden items are gaining traction.

- Google Trends: Input potential product ideas (e.g., “wooden coasters,” “miniature planters”) to see their search popularity over time.

Local Craft Fairs & Farmers Markets: Attend these events in person. Observe what products sell well, how they are displayed, and what prices they command. Engage with vendors if possible to glean insights into their best-sellers.

Local Retailers: Visit small boutiques, gift shops, and even coffee shops that sell local artisan goods. See what kinds of wooden items are stocked and at what price points.

Characteristics of High-Demand Micro-Projects

To ensure a project falls within the “under one hour” timeframe and has strong market appeal, consider these characteristics:

- Simple Design, High Impact: Designs that are easy to cut and assemble but look polished and attractive. Think clean lines, natural wood grain, and minimal joinery.

- Low Material Cost (Scrap Wood!): The primary material cost should be effectively zero, as you’re using scrap. This directly contributes to higher profit margins.

- Broad Appeal: Items that many people can use or appreciate, rather than niche products.

- Customization Potential: Opportunities for simple personalization (e.g., engraving initials, choosing different wood types for contrast) can increase perceived value.

- Minimal Finishing Time: Quick-drying finishes like clear spray lacquer, wipe-on poly, or natural oils are ideal. For projects that might be exposed to moisture, understanding options like can you stain over linseed oil? or linseed oil vs stain can be beneficial.

Top Micro-Projects (Under 1 Hour) with High-Profit Potential

Based on 2026 market trends and the characteristics above, here are some excellent choices for Maximizing Profit from Scrap Wood: High-Demand Micro-Projects Under One Hour:

| Project Idea | Description | Estimated Time | Key Scrap Wood Type | Avg. Selling Price (USD) | Profit Margin Potential |

|---|---|---|---|---|---|

| Coasters (Set of 4) | Square, round, or hexagonal slices of interesting wood, sanded smooth and sealed. | 45-60 min/set | Hardwood offcuts (oak, walnut, maple, cherry) | $15 – $30 | Very High |

| Small Planter Boxes | Miniature boxes (2″x2″ to 4″x4″) for succulents or air plants. Simple butt joints. | 30-50 min/each | Softwood (pine, cedar) or plywood scraps | $10 – $25 | High |

| Wooden Keychains | Small, decorative shapes (circles, houses, animals) with a drill hole for a ring. | 15-30 min/each | Any small, attractive hardwood or exotic wood | $5 – $15 | Very High |

| Phone Stands | Simple angled cuts to create a functional stand for smartphones. | 30-45 min/each | Solid hardwood blocks or dense plywood | $15 – $35 | High |

| Small Decorative Signs | Word cutouts (e.g., “Home,” “Love”) or small framed sayings. | 40-60 min/each | Thin plywood, pallet wood, or pine | $10 – $30 | High |

| Bottle Openers (w/ wood handle) | Attaching a metal opener mechanism to a nicely shaped, small wooden handle. | 20-30 min/each | Exotic wood scraps, sturdy hardwood blocks | $15 – $40 | High |

| Magnetic Knife Strips | A strip of attractive wood with embedded magnets. Requires careful drilling. | 45-60 min/each | Solid hardwood (oak, maple, walnut) | $25 – $50 | Medium-High |

| Tiny Trinket Bowls/Dishes | Carved or routed small depressions in a block of wood for jewelry or coins. | 45-60 min/each | Any dense, attractive hardwood | $20 – $45 | High |

| Custom Wood Tags/Labels | Small, personalized tags for gifts, plants, or organization. | 10-20 min/each | Thin wood scraps (plywood, balsa, thin hardwoods) | $3 – $10 | Very High |

Note: Selling prices are estimates and can vary based on wood type, finish quality, customization, and market.

Remember, the key is to assess your own scrap inventory. Do you have many small blocks of exotic wood? Focus on keychains or bottle openers. Lots of thin plywood? Decorative signs or small plant tags could be your goldmine.

Efficient Production & Quality Finishing for Maximizing Profit

Once you’ve identified your high-demand micro-projects, the next step is to produce them efficiently without sacrificing quality. The “under one hour” constraint demands a streamlined process from start to finish. This is where smart workshop practices and appropriate tooling come into play, directly contributing to Maximizing Profit from Scrap Wood: High-Demand Micro-Projects Under One Hour.

Streamlining Your Workflow: Time is Money ⏱️

Every minute saved in production directly impacts your profit margin.

- Batch Processing: Instead of making one item at a time, cut all identical pieces for multiple items in one go. If you’re making 20 coasters, cut all 80 sides (if square) at once. Then move to sanding all 80 pieces, then assembly, and finally finishing. This reduces setup time for each step.

- Templates and Jigs: Create reusable templates for common shapes or use jigs to ensure precise, repeatable cuts. For instance, a simple crosscut sled with a stop block is invaluable for cutting multiple pieces of identical length on a table saw. Similarly, a doweling jig can speed up small assemblies.

- Dedicated Tool Setup: Have your frequently used tools (e.g., Vintage Delta Scroll Saw, band saw, sander) set up and ready to go. Minimize time spent adjusting settings or changing blades for different operations within the same batch. For a general understanding of essential tools, exploring options for a wooden work table as a dedicated workspace is recommended.

- Optimal Tooling:

- Scroll Saws and Bandsaws: Excellent for cutting intricate shapes in small pieces of wood. A Reliant 14 Bandsaw or similar models are highly efficient for cutting curves and repetitive patterns.

- Table Saws: Essential for precise, repeatable straight cuts. Even smaller models like a Pro Tech 10 Table Saw can be highly effective. Remember to ensure safety with a BORK Riving Knife for safer operations.

- Sanders: Orbital sanders or even a small detail sander are crucial for quick, smooth finishes.

- Drill Press: For consistent, straight holes, especially for keychains or small joinery.

Quality Finishing: The Final Touch 🎨

A simple, attractive finish can elevate a scrap wood item from a craft project to a desirable product. Focus on finishes that are quick to apply and dry.

- Sanding: Start with a coarser grit (100-120) to remove saw marks, then move to a finer grit (180-220) for a smooth feel. For small items, a quick hand sand can often suffice.

- Natural Oils: Food-safe oils (e.g., mineral oil, walnut oil) are excellent for items like cutting board scraps, coasters, or small dishes. They enhance the natural wood grain and dry relatively quickly. Apply, wipe off excess, and let cure.

- Wipe-On Polyurethane: Offers good protection and a lovely sheen. It’s easy to apply with a cloth, dries relatively fast, and multiple thin coats build durability. This is a great option for many projects.

- Spray Lacquer/Polyurethane: Ideal for rapid finishing of many small items. A few quick, light coats dry fast, providing a durable, even finish. Ensure good ventilation when using spray finishes.

- Wax Finishes: Paste wax or beeswax can provide a natural, satin sheen and a pleasant feel. It’s quick to apply and buff.

- Edge Treatment: Consider a slight chamfer or round-over on edges using a router with a small bit or even sandpaper. This adds a professional look and feel.

Finishing Time Breakdown Example (for a set of 4 coasters):

- Sanding (100, 180, 220 grit): 10-15 minutes

- Wipe-on Poly/Oil application: 5 minutes

- Drying time: (Passive, work on next batch)

- Second coat (if desired): 5 minutes

This demonstrates how active finishing time remains low, allowing for high throughput.

“Efficiency in the workshop isn’t just about speed; it’s about intelligent design, repeatable processes, and letting your tools do the hard work. This approach is fundamental to Maximizing Profit from Scrap Wood: High-Demand Micro-Projects Under One Hour.”

Selling Strategies and Marketing Your Micro-Projects

Creating beautiful, high-demand micro-projects from scrap wood is only half the battle. The other half is effectively selling them to maximize your profit. In 2026, a multi-channel approach often yields the best results, combining online presence with local engagement. This strategy is critical for truly Maximizing Profit from Scrap Wood: High-Demand Micro-Projects Under One Hour.

Pricing Your Products Competitively and Profitably

Pricing correctly is crucial. Your price needs to cover your “cost” (even if scrap wood is free, consider the value of your time and consumables like glue, sandpaper, and finish) and provide a healthy profit margin.

- Materials Cost: While scrap wood is “free,” factor in the cost of hardware (key rings, magnet inserts, bottle opener mechanisms), glue, sandpaper, and finishing products.

- Time (Your Wage): Calculate your desired hourly wage. If a coaster set takes you 45 minutes to make, and you want to earn $30/hour, that’s $22.50 in labor costs.

- Overhead: Factor in electricity, tool maintenance, and marketing expenses.

- Market Price: Research what similar items are selling for on Etsy, at local markets, and in boutiques. You want to be competitive but not undervalue your work.

Formula for Basic Pricing: (Material Cost + Labor Cost) x 2 to 3 = Retail Price

The multiplier (2 to 3) accounts for overhead and profit margin. For scrap wood projects with low material costs, you can aim for a higher multiplier.

Sales Channels: Reaching Your Customers 🚀

Utilize a mix of online and offline channels to maximize your reach.

Online Marketplaces:

- Etsy: Still a powerhouse for handmade goods. Focus on high-quality photos, clear descriptions with relevant keywords (e.g., “handmade wooden coasters,” “recycled wood art”), and excellent customer service.

- Your Own Website/Shop: As your business grows, consider a simple e-commerce site (Shopify, Squarespace) to establish your brand and avoid marketplace fees.

- Social Media (Instagram, Facebook, TikTok): Use platforms like Instagram and TikTok to showcase your creative process (time-lapse videos of making an item in under an hour are very engaging!), behind-the-scenes glimpses, and finished products. Use relevant hashtags and interact with potential customers.

Local Craft Shows & Fairs:

- In-person Interaction: Allows customers to see, touch, and feel the quality of your work. This direct interaction often leads to higher sales and repeat customers.

- Display is Key: Create an attractive, professional display. Use different heights, good lighting, and clear pricing. For example, a beautifully crafted woodworking storage bench could be a great display piece for smaller items.

- Small, Grab-and-Go Items: Micro-projects are perfect for impulse buys at craft shows.

- Networking: Connect with other makers and local businesses.

Local Boutiques & Gift Shops:

- Wholesale Opportunities: Approach local shops that align with your brand. Offer a wholesale price (typically 50% of your retail price). This can lead to consistent orders without the direct selling effort.

- Consignment: Some shops may offer consignment, where they pay you only when an item sells. This is lower risk for them but means you wait for payment.

Marketing Strategies for Maximizing Visibility

- Storytelling: Emphasize the “upcycled” or “sustainable” aspect of your products. People appreciate knowing their purchase is eco-friendly. Talk about the type of wood, where it came from (e.g., “repurposed oak from an old barn”), and the care you put into each piece.

- High-Quality Photography: Professional-looking photos are non-negotiable, especially for online sales. Use natural light, clean backgrounds, and show items in context (e.g., coasters on a coffee table, a phone stand holding a phone).

- Bundle Deals: Offer discounts for buying multiple items, e.g., “Buy 3 keychains, get 1 free” or “Coaster set + phone stand bundle.”

- Personalization: If possible, offer simple customization options like engraving initials or a short phrase. This adds significant value and appeal.

- Packaging: Simple, attractive packaging can enhance the unboxing experience. Consider small burlap bags for coasters or kraft paper boxes tied with twine.

- Email List: Collect email addresses at craft shows or through your website to notify customers about new products, sales, or upcoming events.

By combining efficient production of high-demand micro-projects with strategic multi-channel selling and effective marketing, you can effectively turn your workshop’s scrap wood into a thriving and profitable venture in 2026.

Conclusion

The journey of Maximizing Profit from Scrap Wood: High-Demand Micro-Projects Under One Hour is a rewarding one, transforming what many consider waste into valuable, sought-after artisanal goods. In 2026, the market for unique, handmade wooden products is robust, presenting an exceptional opportunity for woodworkers to not only reduce waste but also significantly augment their income.

This comprehensive guide has emphasized the critical steps: beginning with thorough market research to pinpoint truly high-demand items, focusing on micro-projects that can be completed efficiently within an hour, streamlining production with smart tools and techniques, and finally, executing a multi-faceted selling strategy. By adhering to these principles, woodworkers can cultivate a sustainable and profitable side hustle or even a full-time venture.

The beauty of these micro-projects lies in their accessibility and high-profit potential. With minimal material cost and rapid production cycles, the return on your time and effort can be substantial. So, rather than letting those precious wood offcuts gather dust, view them as raw material for creativity and commerce. Equip your workshop, refine your craft, and strategically engage with the market to unlock the full potential of your scrap wood.

Actionable Next Steps:

- Inventory Your Scraps: Categorize your scrap wood by type, size, and potential use.

- Choose 2-3 Target Projects: Based on your scrap inventory and market research, select a few micro-projects to start with.

- Create Prototypes: Make a few prototypes to refine your design and production process, timing yourself to ensure the “under one hour” goal is met.

- Batch Produce: Once happy with your prototypes, produce a small batch (e.g., 10-20 units) of each chosen project.

- Develop Your Brand: Even for small items, consider a simple logo or consistent aesthetic.

- Set Up Sales Channels: Begin with one online platform (like Etsy) and identify one or two local craft fairs to participate in.

Embrace the challenge of transforming the overlooked into the highly desirable. Your workshop’s scrap bin is not a testament to waste, but a treasure chest awaiting discovery.