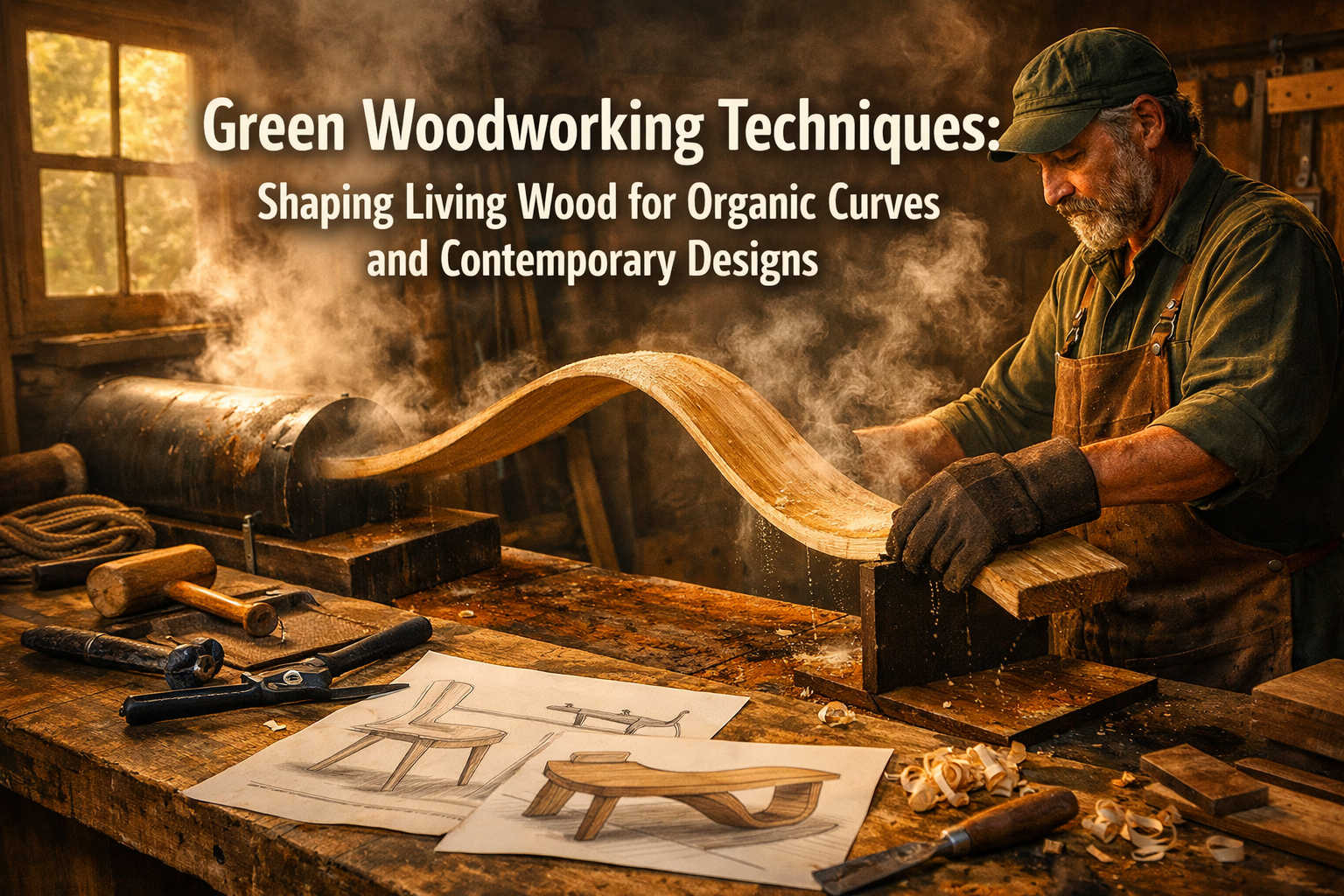

The world of woodworking is constantly evolving, blending age-old traditions with modern innovation. In 2026, a significant trend is the resurgence of authenticity and sustainability, leading many artisans and designers to rediscover Green Woodworking Techniques: Shaping Living Wood for Organic Curves and Contemporary Designs. This approach, which involves working with unseasoned, “green” wood, opens up a realm of possibilities for creating fluid, organic shapes that are difficult, if not impossible, to achieve with kiln-dried timber. Far from being a niche pursuit, green woodworking is a powerful method for crafting stunning, bespoke pieces that resonate with the natural world and modern aesthetic sensibilities.

This hands-on guide will delve into the intricacies of green woodworking and steam bending, bridging traditional techniques with modern digital planning tools. It aims to empower woodworkers to create organic forms that truly embody the authenticity trend dominating design in 2026.

Key Takeaways

- Green woodworking utilizes unseasoned wood, which is softer and more pliable, allowing for easier shaping with hand tools and unique forms.

- Steam bending is a core green woodworking technique that makes wood highly flexible, enabling the creation of dramatic curves and complex geometries.

- Digital planning tools enhance traditional methods, allowing for precise design, jig creation, and efficient material usage, especially for complex organic curves.

- Working with green wood is sustainable, often using locally sourced, smaller timber sections and reducing energy consumption associated with kiln drying.

- Embracing green woodworking techniques leads to distinctive, high-quality pieces with organic curves that meet contemporary design demands for natural beauty and authenticity.

The Foundation: Understanding Green Woodworking Techniques: Shaping Living Wood for Organic Curves and Contemporary Designs

Green woodworking is an ancient craft, practiced for millennia before the advent of sawmills and kilns. It is, at its heart, the art of working with wood as it is found in nature – fresh from the tree, still full of sap and moisture. This “living wood” is inherently different from the dry lumber commonly used in modern workshops. Its high moisture content makes it softer, more flexible, and easier to cut and shape with hand tools, significantly reducing the effort required compared to dry wood.

The defining characteristic of working with green wood is its malleability. While dry wood resists bending and shaping, green wood can be coaxed into various forms through techniques like carving, splitting, shaving, and most notably, bending. This inherent pliability is what allows for the creation of the organic curves and fluid lines that are the hallmark of green woodworking.

Why Choose Green Wood?

There are several compelling reasons why woodworkers in 2026 are increasingly turning to green woodworking:

- Ease of Shaping: The moisture acts as a natural lubricant, making the wood easier to cut, carve, and plane with hand tools like drawknives, spokeshaves, and gouges. This often results in a more enjoyable and less physically demanding woodworking experience.

- Sustainable Practice: Green woodworking often involves sourcing wood locally, sometimes from fallen trees or managed woodlands, minimizing transport and energy-intensive kiln drying. This aligns perfectly with the growing demand for sustainable and eco-conscious craftsmanship.

- Unique Aesthetic: The ability to create flowing, organic curves and forms that are difficult or impossible with dry wood gives green woodworking pieces a distinctive, natural beauty. Each piece becomes a unique expression of the wood’s inherent character and the artisan’s vision.

- Reduced Tool Wear: Working with softer wood can extend the life of hand tools, as they encounter less resistance and dull less quickly than when working with dense, dry hardwoods.

- Direct Connection to Material: There’s a profound satisfaction in working directly with raw, unseasoned timber, feeling its life and transforming it with minimal intervention.

Essential Tools for Green Woodworking

While green woodworking can be incredibly simple, requiring just a few basic hand tools, certain implements are traditionally associated with the craft. These tools are designed to work efficiently with the softer, more yielding nature of green wood.

- Shaving Horse: A versatile workbench that holds the workpiece securely with a foot-operated clamp, leaving both hands free for shaping with drawknives and spokeshaves.

- Drawknife: A long blade with a handle at each end, used for quickly removing large amounts of wood. Its broad cutting edge excels at shaping curves and flats on green timber.

- Spokeshave: Similar to a plane, but with shorter blades and handles, designed for finer shaping and smoothing of curves and contoured surfaces. It’s ideal for refining the forms started with a drawknife.

- Axes and Adzes: Used for cleaving and roughing out large sections of wood, particularly useful when working directly from a log.

- Carving Gouges and Chisels: Essential for detailed carving and hollowing out, allowing for intricate organic shapes and textures.

- Bending Forms/Jigs: Crucial for steam bending, these are custom-made molds that hold the wood in its desired curved shape while it dries.

“Green woodworking is a journey into the heart of the material, allowing the wood to dictate its form while guided by the craftsman’s hand. It’s about coaxing beauty from the natural world.” – A seasoned green woodworker

Working with green wood is not without its challenges. As the wood dries, it will shrink, and if not managed correctly, this can lead to cracking or warping. Understanding wood movement and controlling the drying process is paramount for successful green woodworking. This often involves slow drying, allowing the wood to equalize its moisture content gradually, or by designing pieces where movement is accounted for or embraced as part of the aesthetic.

In 2026, the appeal of crafting bespoke items, like a woodworking nightstand or elements for a woodworking bedroom, with the unique, hand-hewn character that only green woodworking can provide, is stronger than ever.

The Art of Steam Bending: Achieving Organic Curves and Contemporary Designs

Steam bending is arguably the most captivating and transformative of all Green Woodworking Techniques: Shaping Living Living Wood for Organic Curves and Contemporary Designs. This process involves heating unseasoned wood in a steam-filled chamber, which makes the wood fibers pliable and flexible, allowing it to be bent into dramatic curves without breaking. Once bent and held in a form while drying, the wood retains its new shape, creating incredibly strong and beautiful components.

The Science Behind Steam Bending

When wood is subjected to heat and moisture (steam), two key changes occur:

- Lignin Softening: Lignin, the natural glue that binds wood fibers together, becomes plasticized and softens at high temperatures. This allows the wood fibers to slide past each other more easily without fracturing.

- Increased Pliability: The heat and moisture also make the cellulose fibers themselves more flexible.

Together, these effects transform rigid wood into a material that can be bent significantly, much like plastic. The art lies in understanding the limits of different wood species and applying the correct amount of heat and moisture for the right duration.

Setting Up a Steam Bending Operation

A successful steam bending setup typically includes:

- Steam Box: This is a sealed chamber designed to hold the wood planks and fill with steam. It can range from a simple, homemade plywood box to a sophisticated, insulated unit. Key considerations include:

- Size: Long enough to accommodate the longest pieces of wood.

- Insulation: To maintain consistent high temperatures.

- Drainage: To prevent waterlogging inside.

- Safety: Secure latches and a vent for pressure release.

- Steam Generator: This produces the steam that is fed into the box. Options include wallpaper steamers, dedicated steam generators, or even large pots of boiling water with a hose attachment. Consistency and adequate steam volume are crucial.

- Bending Forms/Jigs: These are rigid molds, often made from plywood, MDF, or even metal, that dictate the final curved shape of the wood. They must be strong enough to withstand the considerable springback pressure of the cooling wood. The jig should be ready before the wood comes out of the steam box, as the bending must happen quickly.

- Clamps: Plenty of strong clamps are needed to secure the hot, pliable wood firmly against the bending form until it cools and dries.

- Strap (Optional but Recommended): For tight bends, a metal strap (or a strong composite strap) wrapped around the outside of the wood helps prevent tension cracks on the outer edge of the bend.

The Steam Bending Process: A Step-by-Step Guide

- Select Your Wood: Use green, unseasoned wood. Freshly cut wood (within a few weeks) is ideal. Hardwoods like oak, ash, walnut, and cherry are excellent candidates for steam bending due to their long, straight grain structure.

- Prepare the Wood: Cut the wood to the desired dimensions. Avoid knots and cross-grain, as these areas are prone to breaking. The thickness of the wood will dictate the steaming time and the radius of the bend achievable.

- Heat the Wood: Place the wood in the steam box. A general rule of thumb for steaming time is one hour per inch of thickness for hardwoods, though this can vary. Ensure the steam box maintains a consistent, high temperature (around 200-212°F or 93-100°C).

- Bend Immediately: Once steamed, quickly remove the wood and immediately place it into your pre-prepared bending form. This is a race against the clock, as the wood begins to cool and stiffen rapidly.

- Clamp Securely: Apply strong clamps along the length of the wood, pressing it firmly against the bending form. If using a strap, position it correctly to compress the outer fibers.

- Dry and Set: Allow the wood to cool and dry completely in the form. This can take several days to weeks, depending on the wood species, thickness, and ambient conditions. The wood must be fully dry before removing it from the form to minimize springback.

- Release and Refine: Once dry, carefully remove the wood from the form. There will be some “springback” (the wood partially unbending), which should be accounted for in your jig design. The piece can then be further shaped, planed, sanded, and finished. For further insights on finishing techniques, consider exploring resources on high gloss wood finishing techniques or rustic wood finishing techniques to complement your organic curves.

| Wood Species | Ease of Bending | Typical Max Thickness (for tight bends) | Common Uses in Green Woodworking |

|---|---|---|---|

| Ash | Excellent | 1.5 – 2 inches | Chairs, tool handles, sporting goods |

| Oak (Red/White) | Good | 1 – 1.5 inches | Furniture, boat building |

| Cherry | Good | 1 – 1.25 inches | Fine furniture, decorative elements |

| Walnut | Moderate | 0.75 – 1 inch | Smaller curved components |

| Maple | Moderate | 0.75 – 1 inch | Furniture, decorative elements |

Bridging Traditional Craft with Digital Planning in 2026

The integration of digital planning tools, such as CAD software (e.g., Fusion 360, SketchUp) and CNC machining, has revolutionized the creation of bending forms and jigs in green woodworking. In 2026, designers can:

- Design Complex Curves Precisely: Create intricate, flowing organic curves in 3D software, visualizing the final product before cutting any wood.

- Optimize Jig Design: Generate precise templates for bending forms, ensuring accurate and repeatable results. CNC machines can then cut these forms with incredible accuracy, eliminating tedious hand-shaping of jigs.

- Anticipate Springback: Some advanced software allows for simulations that help predict the degree of springback, enabling the creation of forms that over-bend slightly to achieve the desired final curve.

- Material Optimization: Digital tools can help nest components efficiently, minimizing waste when cutting blanks for steam bending.

This blend of ancient craft with modern technology allows artisans to push the boundaries of design, crafting bespoke furniture and architectural elements with an unprecedented level of precision and organic fluidity. The marriage of these approaches truly elevates Green Woodworking Techniques: Shaping Living Wood for Organic Curves and Contemporary Designs to meet the sophisticated demands of contemporary design in 2026.

Crafting Contemporary Designs with Green Woodworking Techniques: Shaping Living Wood for Organic Curves and Contemporary Designs

The true power of Green Woodworking Techniques: Shaping Living Wood for Organic Curves and Contemporary Designs lies in its capacity to break free from the rectilinear constraints of traditional dry lumber construction. By embracing the malleability of living wood, artisans can create furniture and art pieces that feature dramatic, sweeping curves, ergonomic shapes, and a profound connection to the natural world. This approach is perfectly aligned with the authenticity trend of 2026, where consumers seek products that tell a story, are sustainably made, and possess unique, handcrafted character.

From Forest to Form: A Design Philosophy

The design process in green woodworking often begins with the wood itself. Instead of imposing a rigid design onto a material, the wood’s natural characteristics—its grain, its sapwood and heartwood, even its slight natural bends—can inspire and inform the final shape. This “designing with the wood” philosophy results in pieces that feel organic, harmonious, and truly unique.

Consider the journey:

- Sourcing: Often, wood is sourced locally, perhaps from a felled tree or a sustainably managed forest. This direct connection to the raw material instills a sense of purpose and ecological responsibility.

- Initial Shaping: Using axes and drawknives, the wood is quickly roughed out, following the natural grain to maximize strength and minimize waste.

- Steam Bending: Where curves are desired, the magic of steam transforms rigid planks into pliable ribbons, ready to be coerced into elegant arcs and spirals.

- Refinement: Spokeshaves, carving gouges, and other hand tools are then used to refine the forms, creating smooth transitions and tactile surfaces. The wood’s inherent beauty is highlighted through careful finishing. For those interested in enhancing the natural beauty of wood, exploring dark wood finishing techniques or methods for mahogany wood finishing could offer additional design possibilities, even for green wood projects post-drying.

Applications in Contemporary Design

Green woodworking techniques lend themselves to a wide array of contemporary applications:

- Ergonomic Furniture: Chairs, benches, and loungers can be designed with backs and seats that perfectly conform to the human body, providing unparalleled comfort through naturally sculpted curves. Imagine a dining chair with a backrest that gracefully cradles the spine, impossible to achieve with standard milling.

- Sculptural Elements: The ability to create dramatic, flowing forms makes green woodworking ideal for artistic installations, wall hangings, and decorative objects that serve as focal points in a space.

- Lighting Fixtures: Delicate, bentwood shades or bases can create stunning light features that cast beautiful shadows and bring a warm, organic glow to any interior.

- Architectural Details: Handrails, door frames, or even ceiling elements can be crafted with bespoke curves, adding a touch of bespoke artistry and natural fluidity to a building’s interior.

- Sustainable Home Goods: From fruit bowls to storage solutions, green woodworking allows for the creation of everyday items that are both beautiful and environmentally conscious.

- Live Edge Furniture Integration: While primarily for seasoned wood, green woodworking principles of embracing natural form complement the aesthetic of live edge wood, allowing for unique combinations of bent components and natural slab tops.

Design Principles for Organic Curves

When designing with green woodworking in mind, consider these principles:

- Fluidity: Aim for smooth, continuous lines and transitions. Avoid abrupt angles unless intentionally used for contrast.

- Balance: Even with organic shapes, ensure the piece feels stable and visually balanced.

- Ergonomics: For functional pieces, consider how the curves interact with the human body.

- Material Honesty: Let the wood’s natural characteristics shine through. Minimal finishes often work best to highlight the grain and texture.

- Embrace Imperfection: The beauty of handmade, natural forms often lies in slight variations, rather than perfect, machine-made uniformity.

Table: Comparing Design Approaches

| Feature | Traditional Dry Woodworking | Green Woodworking & Steam Bending |

|---|---|---|

| Material State | Kiln-dried, low moisture | Freshly cut, high moisture |

| Primary Forms | Straight lines, planar surfaces | Organic curves, flowing forms, ergonomic |

| Shaping Method | Sawing, routing, machine planing | Hand tools (drawknife, spokeshave), steam bending |

| Tooling | Power tools (table saw, planer) | Primarily hand tools, custom jigs |

| Aesthetic | Structured, geometric, precise | Natural, fluid, handcrafted, unique |

| Sustainability | Can be energy-intensive (kiln) | Lower energy, often local sourcing |

| Design Flexibility | Limited by wood’s rigidity | High flexibility for complex curves |

| Post-Shaping | Joinery, assembly | Drying, minimal joinery, natural movement |

The trend in 2026 for authenticity and connection to nature means that pieces crafted using these time-honored yet forward-thinking green woodworking techniques are more coveted than ever. From sophisticated custom furniture to unique art pieces, the ability to shape living wood into organic curves offers an unparalleled opportunity to create designs that are both beautiful and deeply meaningful. For those looking to further their skills, consider taking a woodworking class to master these intricate methods.

Conclusion

The journey into Green Woodworking Techniques: Shaping Living Wood for Organic Curves and Contemporary Designs is a rewarding exploration of tradition, sustainability, and artistic expression. In 2026, as the demand for authenticity and bespoke craftsmanship continues to rise, the ability to transform unseasoned wood into flowing, organic curves through skilled handwork and the magic of steam bending offers a unique advantage. This approach not only results in visually stunning and ergonomically superior designs but also fosters a deeper connection to the material and a more sustainable practice.

By combining the timeless wisdom of working with living wood and the transformative power of steam bending with the precision of modern digital planning tools, woodworkers are empowered to create pieces that are truly exceptional. These are not merely functional objects but sculptural statements that embody natural beauty, individual artistry, and a commitment to thoughtful creation. The organic curves and contemporary designs born from these techniques stand as a testament to the enduring allure of handcrafted quality and the infinite possibilities held within a piece of green timber.

Actionable Next Steps

- Start Small: Begin with simple green woodworking projects like spoons, small bowls, or practice steam bends on scrap pieces to get a feel for the material.

- Invest in Key Hand Tools: Acquire a good quality drawknife, spokeshave, and a reliable shaving horse. These will be your primary companions.

- Build a Basic Steam Box: Construct a simple steam box and generator. Many online tutorials offer guidance for inexpensive, effective setups.

- Experiment with Wood Species: Research and experiment with different types of green wood to understand their bending characteristics and workability. Ash and oak are excellent starting points for steam bending.

- Explore Digital Design: Familiarize yourself with basic CAD software to design your bending forms and visualize complex curves before you begin cutting.

- Join a Community: Connect with local green woodworking guilds or online forums. Sharing knowledge and experience is invaluable.

- Embrace the Process: Green woodworking requires patience and a willingness to learn from the wood itself. Enjoy the journey of bringing organic forms to life.

SEO Meta Title: Green Woodworking: Shaping Organic Curves & Designs in 2026 SEO Meta Description: Explore green woodworking techniques for shaping living wood into organic curves and contemporary designs. A guide to steam bending & sustainable craft in 2026.